The “aha moment” is when you discover the cause for an unexplained condition. In the practice of engineering we use the principles of mathematics, science, all available information and common sense (common to). In the case of mathematics and science are based on proven techniques that are relevant to specific assumptions. The availability of information such as current loading, support strength, type of material, variability of site conditions, etc. is not always available and assumptions are made based on your education, knowledge and experience. Common sense can be complicated, as it depends on how you communicate the issues to a broader audience. This can result in a discussion of what is “common to” the individuals’ knowledge and experience and what is important.

In my experience as a practicing engineer, an answer to a problem is not always immediately apparent. In March of 2008, a generator transport activity during an unusually rainy season occurrence resulted some road damage. This unexplained condition is based on a road segment with adequate drainage, loading capacity and additional surface stiffness from 1” plates. The haul route for this generator move started at the rewinding staging area concrete pad and surrounding by a yard area and roadway to the main road that was supported by 4” base and 2” surface coarse of crushed limestone gravel. The road from the staging yard to the main road was unspecified asphalt coarse. The road damage only occurred at the transition from yard to the asphalt road where the 1” plates were laid for additional load distribution. The main road is a standard asphalt pavement with 1-1/2” plant mixed BIT surface, coarse 1-1/2” mixed BIT binder and 6” aggregate base coarse and was the original haul route for the site excavation. The access road to the rewinding building was on 3” coarse gravel. Finally, the plant original site subgrade was removed, dewatered and replaced with highly compacted river sand that is typical of the power plants industry near a river channels. This loading from the generator and Goldhofer transport vehicle had a total weight of approximately 1.3 million lbs. This loading condition was greater than all previous site-transport. The conclusion of this transport and rigging for the replacement of generator and stator project was a success and the road damage was a minor issue, but was unexplained and contrary to common sense (common to).

In my experience as a practicing engineer, an answer to a problem is not always immediately apparent. In March of 2008, a generator transport activity during an unusually rainy season occurrence resulted some road damage. This unexplained condition is based on a road segment with adequate drainage, loading capacity and additional surface stiffness from 1” plates. The haul route for this generator move started at the rewinding staging area concrete pad and surrounding by a yard area and roadway to the main road that was supported by 4” base and 2” surface coarse of crushed limestone gravel. The road from the staging yard to the main road was unspecified asphalt coarse. The road damage only occurred at the transition from yard to the asphalt road where the 1” plates were laid for additional load distribution. The main road is a standard asphalt pavement with 1-1/2” plant mixed BIT surface, coarse 1-1/2” mixed BIT binder and 6” aggregate base coarse and was the original haul route for the site excavation. The access road to the rewinding building was on 3” coarse gravel. Finally, the plant original site subgrade was removed, dewatered and replaced with highly compacted river sand that is typical of the power plants industry near a river channels. This loading from the generator and Goldhofer transport vehicle had a total weight of approximately 1.3 million lbs. This loading condition was greater than all previous site-transport. The conclusion of this transport and rigging for the replacement of generator and stator project was a success and the road damage was a minor issue, but was unexplained and contrary to common sense (common to).

In August of 2014 I was asked to independently review another site’s generator and transformer project for their heavy load transport activity. Any heavy load transport review must start with determining the site’s geological relationship to the underground structure with a focus on structures, system and components using the Boussinesq method to determine the depth of significant influence (DOSI) that is:

In August of 2014 I was asked to independently review another site’s generator and transformer project for their heavy load transport activity. Any heavy load transport review must start with determining the site’s geological relationship to the underground structure with a focus on structures, system and components using the Boussinesq method to determine the depth of significant influence (DOSI) that is:

“The depth DS is a finite depth below which there are no significant strains in the soil mass due to the loads imposed at the surface.” (FHWA NHI-06-088, 2006)

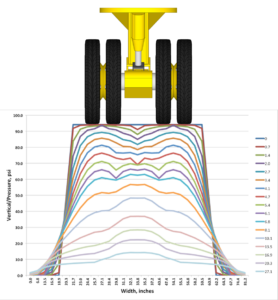

Determining the soil mass spatial attenuation (SMSA) begins with determining the tire contact area. So in considering the tire wheel load(s), spacing and contact area, pavement type, and sub-grade layer(s) spatial attenuation as a function of depth using Boussinesq method and charts prepared by Foster and Alvin that are subsequently refined by Alvin for determining stress, strain and deflection at any point in a homogenous soil mass result in an accurate picture of site grade vulnerabilities. However, the practice of laying down steel plate increases the contact area to reduce sub-surface stress and increases tensile and horizontal shear stress at the bottom surface layer as described by (Yoder and Witczak) that is as follows:

“However, a very important fact that should be clearly understood by the reader that even though stiffer material reduce the risk associate with a sub-grade mode of distress, such as shear, the presents of this stiff layer brings about an increase in the tensile stress magnitude at the bottom of this layer as well as a mark increase in the horizontal shear stresses. Thus a subsequent design analysis is required to insure that both the shearing resistance and the flexure resistance of this stiff layer are great enough to sustain these higher stress conditions.”

The transport vehicle crew’s experience for a wet soil condition was to apply a steel plate to increase sub-soil stiffness. However, the unspecified asphalt road horizontal shear and flexure resistance was not adequate. In addition the sub-grade crushed limestone grave was capable of supporting the transport vehicle loading in wet condition. The important issue is there was no weak sub-grade condition and applying addition stiffness significantly increased asphalt road distress, the “Aha Moment.” The decision was based on only one engineering principle that was common to the crew’s experience that needed the “The 4D Solution” to understand all loading conditions.